High-performance CNC busbar punching and shearing machines for British electrical fabricators. Achieve burr-free shearing and precision punching for copper & aluminium conductors. Engineered for heavy-duty switchgear and control panel manufacturing. Fully automated systems with CAD/CAM integration to streamline your workshop. UK-wide shipping and technical support available. Browse our precision range today.

HQ600-S-7P CNC Busbar Punching & Shearing Machine | High-Speed Fabrication Centre for UK Switchgear & Control Panel Manufacturers

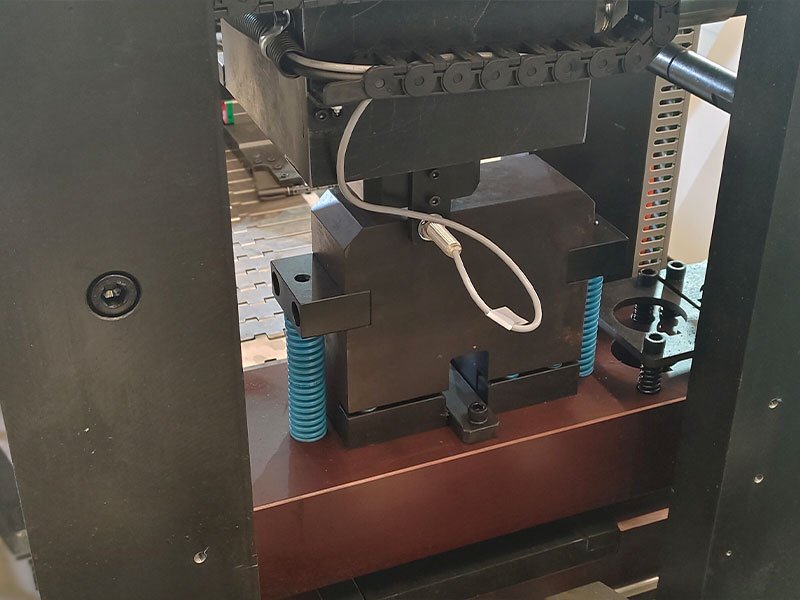

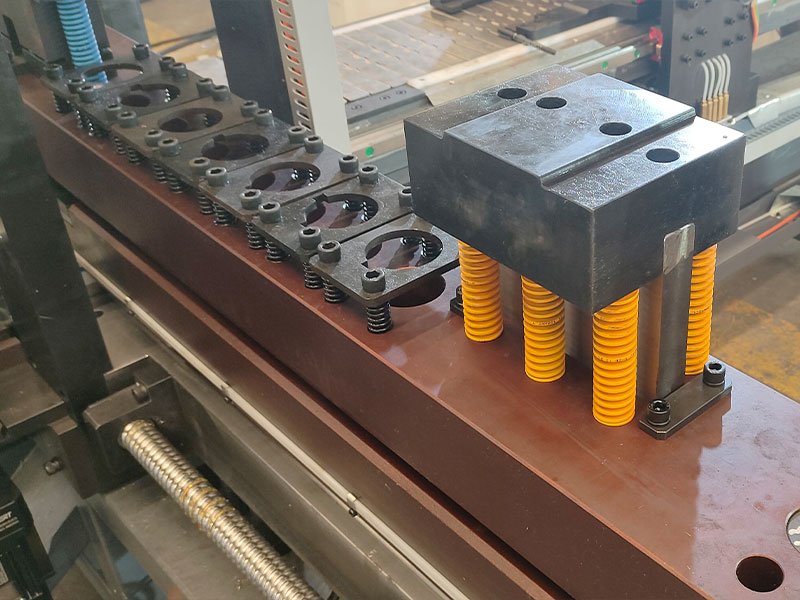

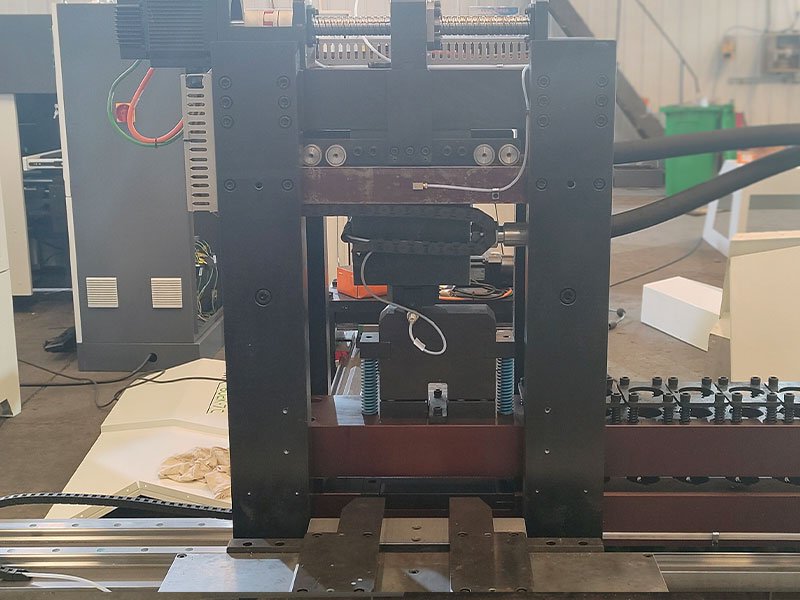

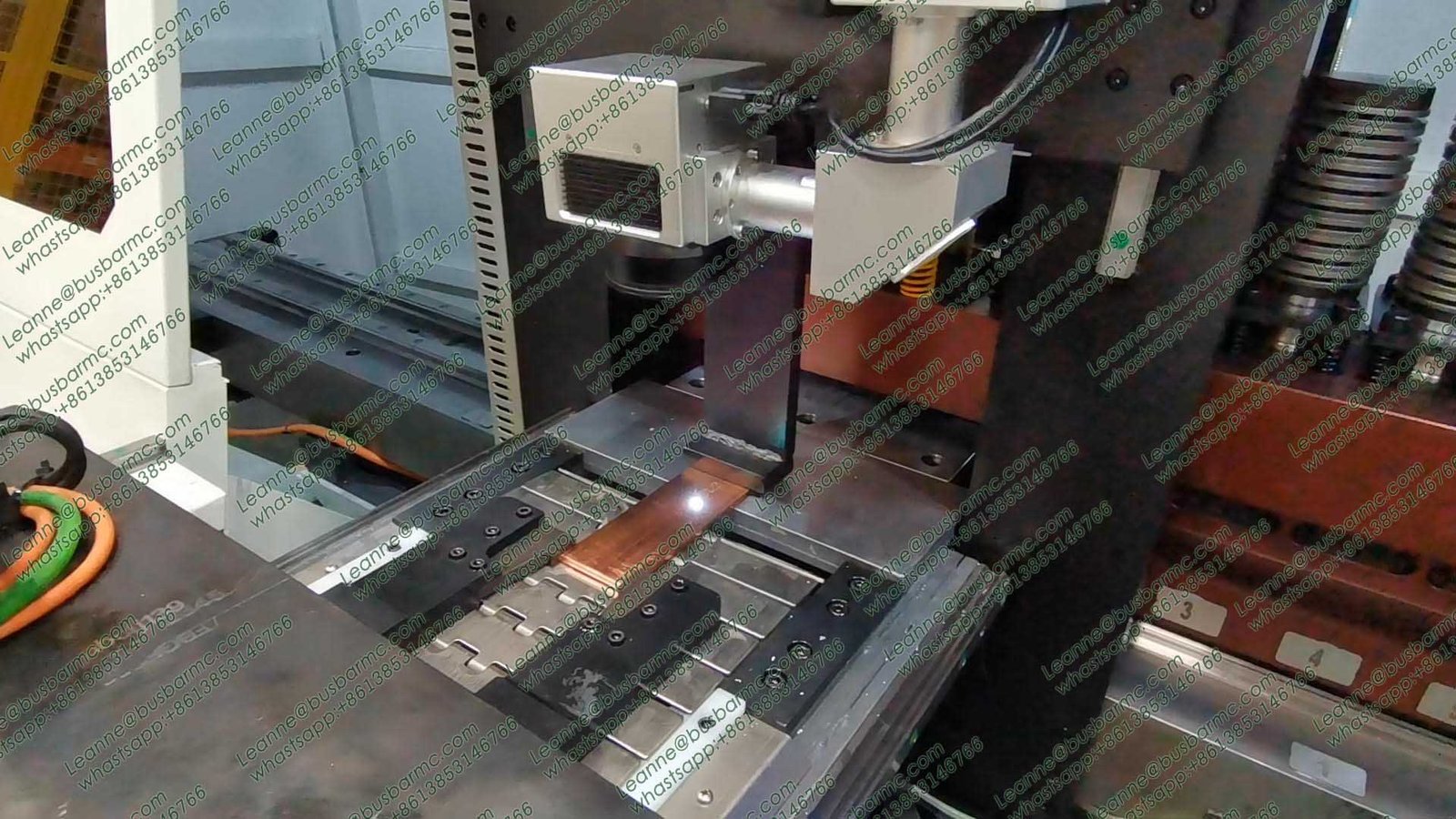

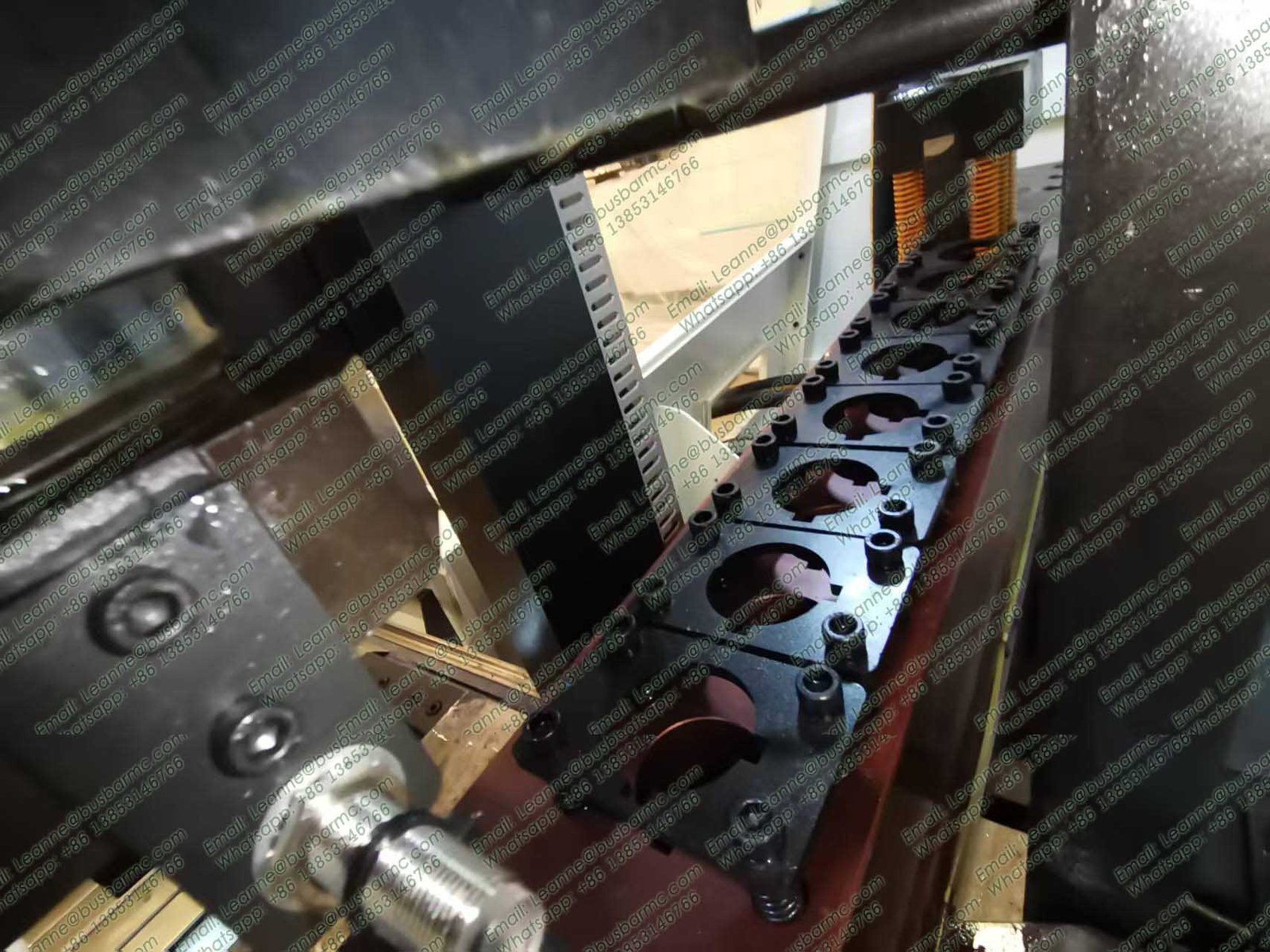

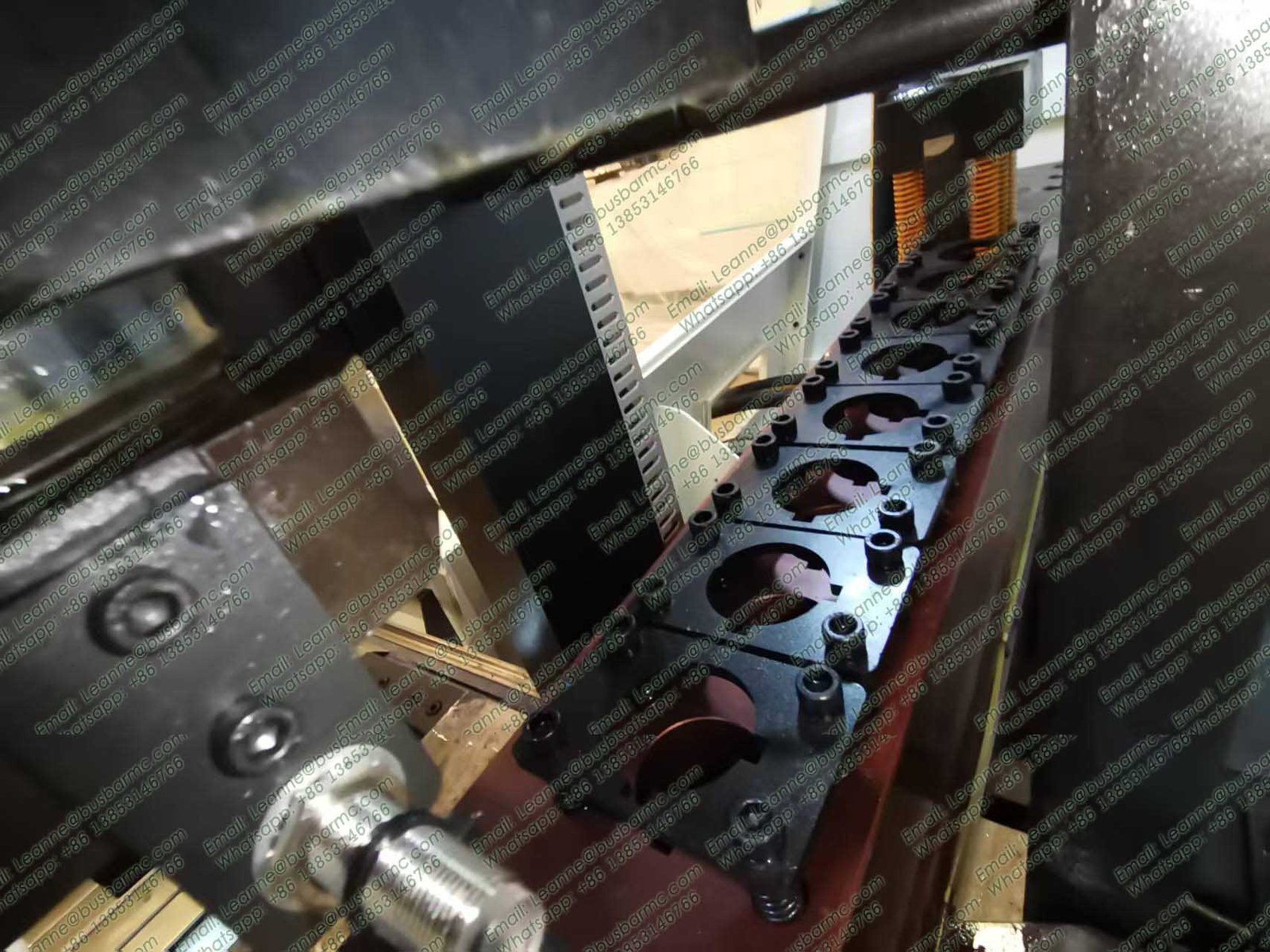

The LTMC HQ600-S-7P is a flagship busbar processing machine designed for the precision-driven UK electrical industry. This high-performance CNC system seamlessly integrates punching and shearing operations into a single automated workflow. The HQ600-S-7P features a robust straight-column mold frame with a 7-punch, 1-shear, and 1-emboss configuration, ensuring perfect concentricity of the upper and lower dies even under heavy industrial use.

Specifically engineered for the British CNC busbar punching and shearing market, this machine is equipped with a world-class Beckhoff control system and CAD/CAM software. This setup dramatically increases production throughput for copper and aluminium conductor fabrication while maintaining strict compliance with BS EN standards. To receive a bespoke quote on the latest busbar shearing machine prices for your UK workshop, contact our technical team today.

LT Busbar Fabrication & Shearing Videos:

Technical Information & Gallery:

HQ600-S-7P CNC Busbar Fabrication Centre Specifications

| Model | HQ600-S-7P |

| Maximum Force (Shearing & Punching) | 600KN |

| Feeding Station Size | 3000x500mm |

| Discharge Station Size | 2500x500mm |

| Maximum Bar Size (Plate) | 6000x200x15mm |

| Maximum Processing Thickness | 15mm |

| Maximum Processing Width | 200mm |

| Maximum Punching Diameter | Ø4.3-Ø55mm |

| Number of Shearing Dies | 1 |

| Number of Punching Dies | 7 |

| Number of Embossing Molds | 1 |

| X-Axis Maximum Travel | 2000mm |

| X-Axis Accuracy Error | 0.10/500mm |

| Y-Axis Maximum Travel | 960mm |

| Y-Axis Accuracy Error | 0.10/500mm |

| Z-Axis Maximum Travel | 310mm |

| X-Axis Maximum Positioning Speed | 75m/min |

| Striking Cylinder Stroke | 45mm |

| Number of Control Axes | 6 |

| Overall Dimensions (LxWxH) | 10500x2750x1800mm |

| Machine Weight | 6700kg |

Advanced Machine Features:

Straight-Column Inline Die Library (7 Punch + 1 Shear + 1 Emboss): Our unique single-row die configuration ensures absolute concentricity for both punching and shearing tasks. While maintaining elite efficiency (40m/min), the system offers precision control down to 0.1mm/500mm, critical for high-end UK switchboard fabrication equipment users.

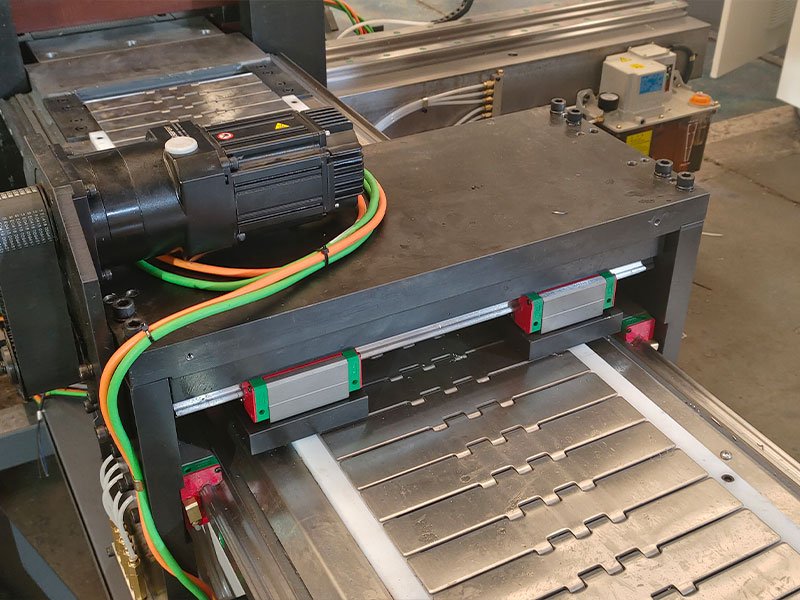

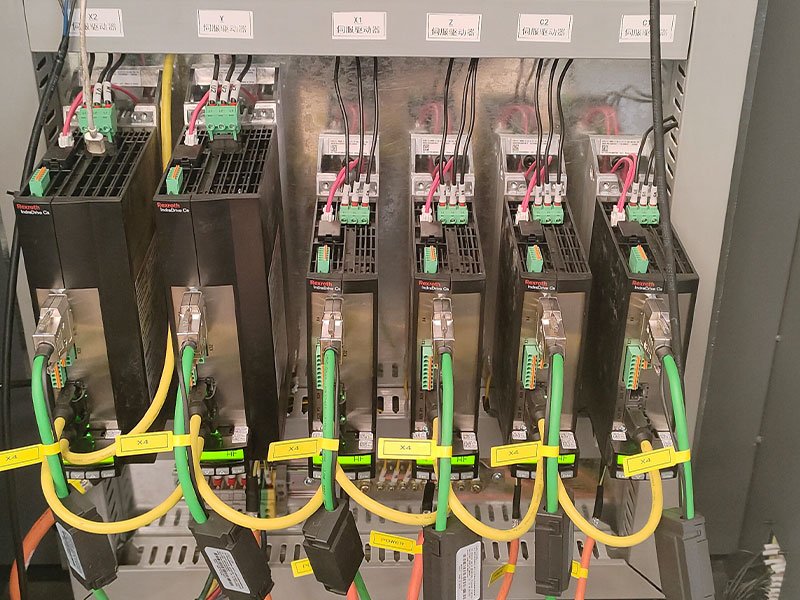

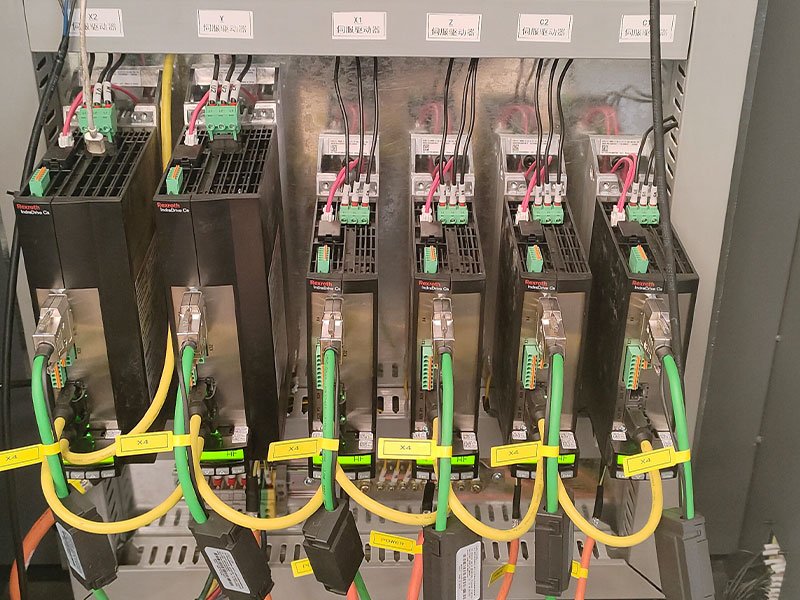

High-Speed 6-Axis Servo Motion System: Powered by 6 individual Rexroth servo servers and motors, the system achieves an X-axis positioning speed of up to 75m/min (150m/min no-load). This is made possible by our dual-clamp technology (X1 and X2), which optimizes feeding and discharge cycles to maximize production output in busy British workshops.

Swiss ABB Motor & 600KN Hydraulic Force: Reliability is key for UK energy distribution projects. The hydraulic station utilizes a Swiss-made ABB motor to generate a consistent 600KN of pressure, dedicated entirely to the punching and shearing unit for maximum stability and burr-free finishes.

Premium German Beckhoff Control & Rexroth Servos: The HQ600-S-7P utilizes the German Beckhoff closed-loop control system, offering superior anti-interference and adaptive capabilities compared to standard open-loop systems. By using internationally renowned components like Rexroth, we ensure lower maintenance costs and higher uptime for UK switchgear fabricators.

UK Industry FAQ – HQ600-S-7P CNC Busbar Centre

1. Which UK industries is this machine suited for?

It is specifically designed for high-volume switchgear fabrication, control panel building, and power distribution enclosure manufacturing across the UK and Ireland.

2. Can it handle large copper conductors?

Yes, the machine handles plates up to 6000mm in length and 15mm in thickness, perfect for industrial-grade copper and aluminium busbars.

3. How does the inline die library improve efficiency?

By having 7 punching, 1 shearing, and 1 embossing die in a single row, tool change times are minimized and alignment remains perfect, ensuring burr-free shearing every time.

4. Is the control system compatible with British electrical design standards?

The CAD/CAM integration allows for direct import of drawings, ensuring all fabricated conductors meet precision specifications required for BS EN standards.

5. What is the positioning accuracy of the CNC system?

The system offers an accuracy error of only 0.10mm per 500mm, driven by high-precision Rexroth servo motors.

6. Does the machine support automatic embossing?

Yes, the inline library includes a dedicated embossing station for part identification and safety marking during the fabrication process.

UK Industry Tags & Hot Tags:

Busbar processing machine UK, CNC busbar shearing and punching London, automatic busbar fabrication equipment Birmingham, copper bar shearing centre Manchester, industrial busbar puncher Leeds, hydraulic busbar station UK, switchgear manufacturing tools Scotland, BS EN compliant busbar machines, precision copper bar fabrication, automated switchboard bender UK, heavy-duty busbar shearing unit, CNC conductor processing.

Localized UK Industry Keywords:

Switchgear busbar shearing machine, British copper bar fabrication tools, CNC busbar punching unit,

automated electrical conductor processing, industrial busbar manufacturing UK, control panel copper tools,

burr-free busbar shearing, high-speed CNC busbar fabrication London, Rexroth powered busbar machine,

Beckhoff busbar control system, industrial switchboard copper bender, heavy duty busbar puncher UK.